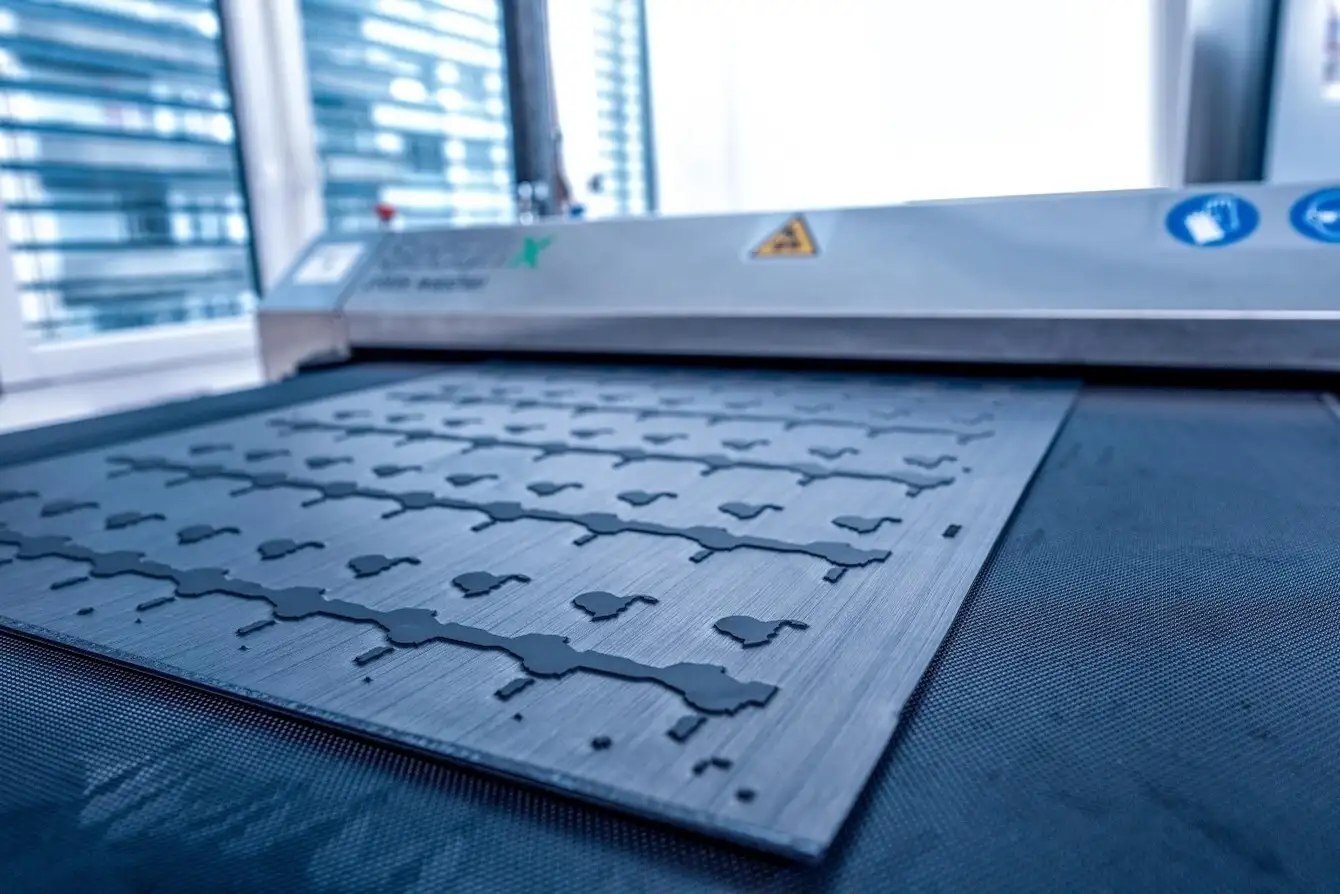

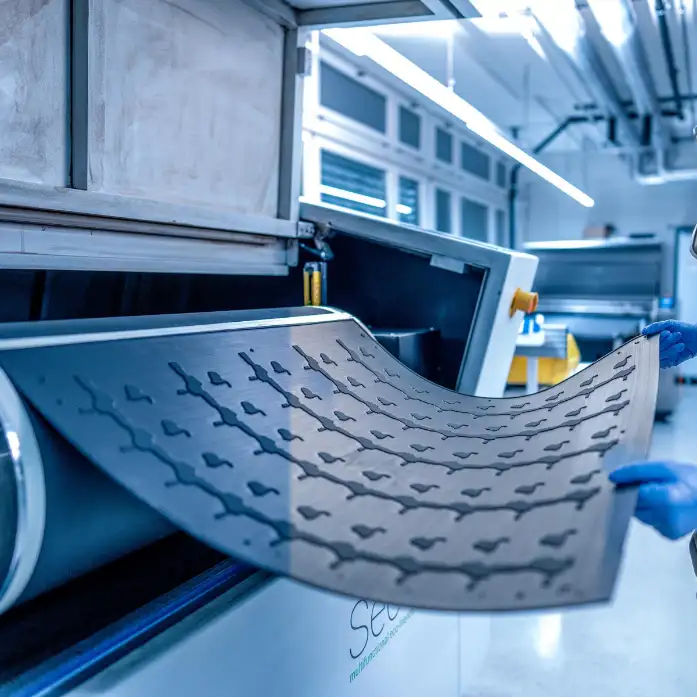

Early 2025, Orell Füssli announced that it had invested in a new S-DLE® Steel Direct Laser Engraving machine for its intaglio plate making. To enhance precision and sustainability even further, Orell Füssli has newly invested in a SecuriX Engraver. This advanced technology has been fully integrated into production, allowing for greater precision, flexibility, and environmental efficiency in the creation of security printing plates, like for offset, intaglio stencil, several imprint and varnish plates. The SecuriX Engraver was developed by DROP AG, a Swiss company recognized for its precision laser systems and process automation solutions tailored to prepress for screen and flexo printing.

Precision and performance for demanding designs

The SecuriX Engraver achieves engraving resolutions of up to 10.160 dpi, using a fiber laser with a switch modulator resulting in faster engraving times and improved performance. By processing digital data directly, it eliminates intermediate steps and significantly increases automation in the prepress workflow. This technology enables the production of extremely fine microtext, modulated lines, and stable line grids with thicknesses of 10 micron (µm) and less, all of which enhance protection against counterfeiting.

The system is fully compatible with offset and intaglio printing and shows improved ink transfer for solvent and mineral oil based inks in combination with a significantly longer running performance in full production mode. It also supports plate preparation for numbering and varnishing processes. Importantly, no modifications are needed for existing printing equipment, allowing for seamless integration into current production environments.

The introduction of the new technology has led to a marked improvement also in operational efficiency, primarily through significantly reduced setup times for the machines. One of the standout factors is the notably longer lifespan of the plates and stencils, which is a clear advancement over the previous manufacturing process. Additionally, the enhanced separation of IRA and IRT colors is a qualitative leap forward, particularly in minimizing IR contamination. This contributes significantly to increased process reliability and higher end-product quality resulting in increased machine availability, more efficient production planning, and reduced downtime.

One of the main advantages of Securi X technology is the maximum flexible combination of wet and dry plates, which is no longer a limitation. The engraving precision also offers clear advantages in intaglio printing, enabling more accurate colour separation and finer detailing. This results in improved registration and print quality, particularly in complex multicolour banknote elements and “modulated lines with dashes”.

Sustainable, safe and simplified

The SecuriX technology avoids the use of photopolymers, solvents, and chemical washout solutions traditionally required in plate preparation. The cleaning process uses only water and brushes, resulting in minimal waste and no hazardous materials. Compared to conventional photopolymer flexographic plates, the environmental impact is significantly reduced, generating less than 30% waste and only 20% of the CO₂ pollution.

Printing plates made from EPDM/NBR materials are both dimensionally stable and extremely durable, supporting longer press runs with consistent quality and less abrasion. This contributes to both sustainable resource use and cost efficiency over time.

«

The SecuriX Engraver has allowed us to take a further step forward in both process sustainability and design precision. It’s a highly flexible system that integrates seamlessly into our production while offering advanced capabilities for today's security printing needs.

» — Julian Becher, Head of Design & Prepress DepartmentDeeper partnership ahead

Both companies, Orell Füssli Ltd. Security Printing and Drop AG share a relentless commitment to delivering efficient, and sustainable printing solutions, along with secure yet visually striking products. The co-development of the SecuriX Engraver signifies a profound collaboration between these two innovative organizations. Through this partnership, Orell Füssli will serve as the global hub for testing innovations and plate-making advancements along with other services with Drop AG.

Both companies are excited about this forward-thinking cooperation and very eager to enhance the security printing industry with high-precision solutions that meet the demands of the future.

With the implementation of the SecuriX Engraver and cooperation with Drop AG, Orell Füssli once again demonstrates its commitment to sustainable innovation, operational excellence, and the ongoing evolution of high-security printing technologies.